Is a “0” Leakage Rate Possible?

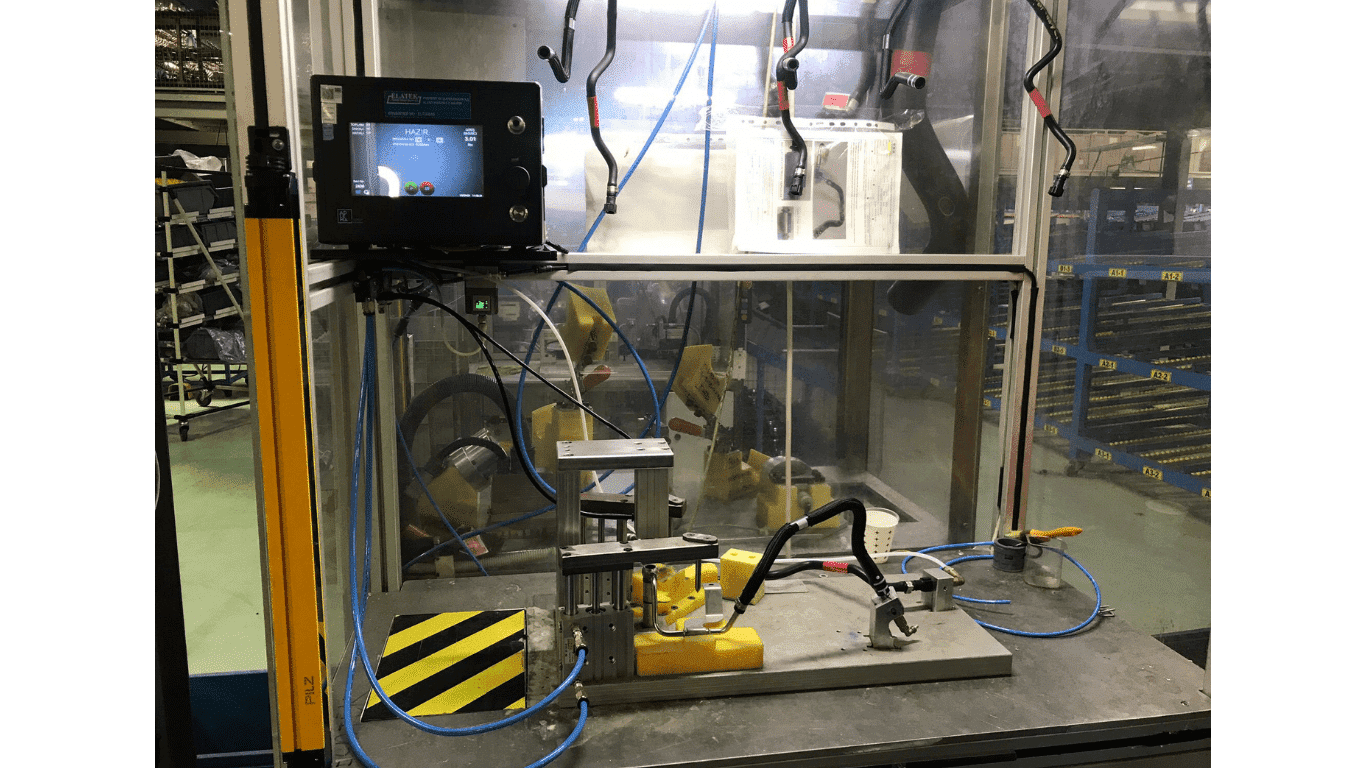

Whether done by pressure decay method or helium mass spectrometry, leak tests are among the critical quality control tests performed during the production phase. Leak tests, a non-destructive testing method, are applied to products produced in many industries. At this point, manufacturers who invest in a leak test device may expect a “0” leakage rate in their products. But “0” leak rate production is not possible. When determining the leak test parameters, the material, place of use, and purpose of the product should be taken into account, instead of a single parameter valid for all products or a “0” leak rate. You can take a look at this article to learn how the test parameters are determined.

Tolerance

With the industrial revolution in the 20th century, production began to be done in large factories instead of small workshops. The production, which started with machines instead of manual production, allowed the production of parts with smaller tolerances. In this way, it was possible to produce all sub-components of a product by independent manufacturers in different production areas and assemble them in a single assembly plant. Today, although our production capability is possible in much smaller tolerances, the tolerance required in different industries differs. It is unnecessary and costly for an automotive factory to produce with the tolerance value required for a spacecraft part.

Even in very sensitive production, the dimensions of the produced parts differ in the normal distribution. Leak tests are also similar to dimensional tolerances. Determining the acceptable amount of leakage is important to avoid unnecessary quality control costs and to avoid unnecessary changes in production and design. Within the leakage tolerance range determined for each product, the leak rate should be determined where the efficiency does not decrease and it works at the optimum level. The range in which the leakage rate falls within the tolerances is considered sealed for the product.

Leakproofness

We talked about the meaninglessness of waiting for a “0” leak rate in all manufactured products. We can say that the term leakproof varies from product to product and there is no generally accepted definition and parameter. Sealing can be tried to be understood through various purposes of use, types of material, and results.

Car Tire

Tire pressure dropping from 23 psi to 20 psi in 6 months isn’t alarming, but if a home refrigerator needs refrigerant refilling every 6 months, it indicates a leak. Despite passing leak tests, both products are considered leakproof based on their specific intended parameters.

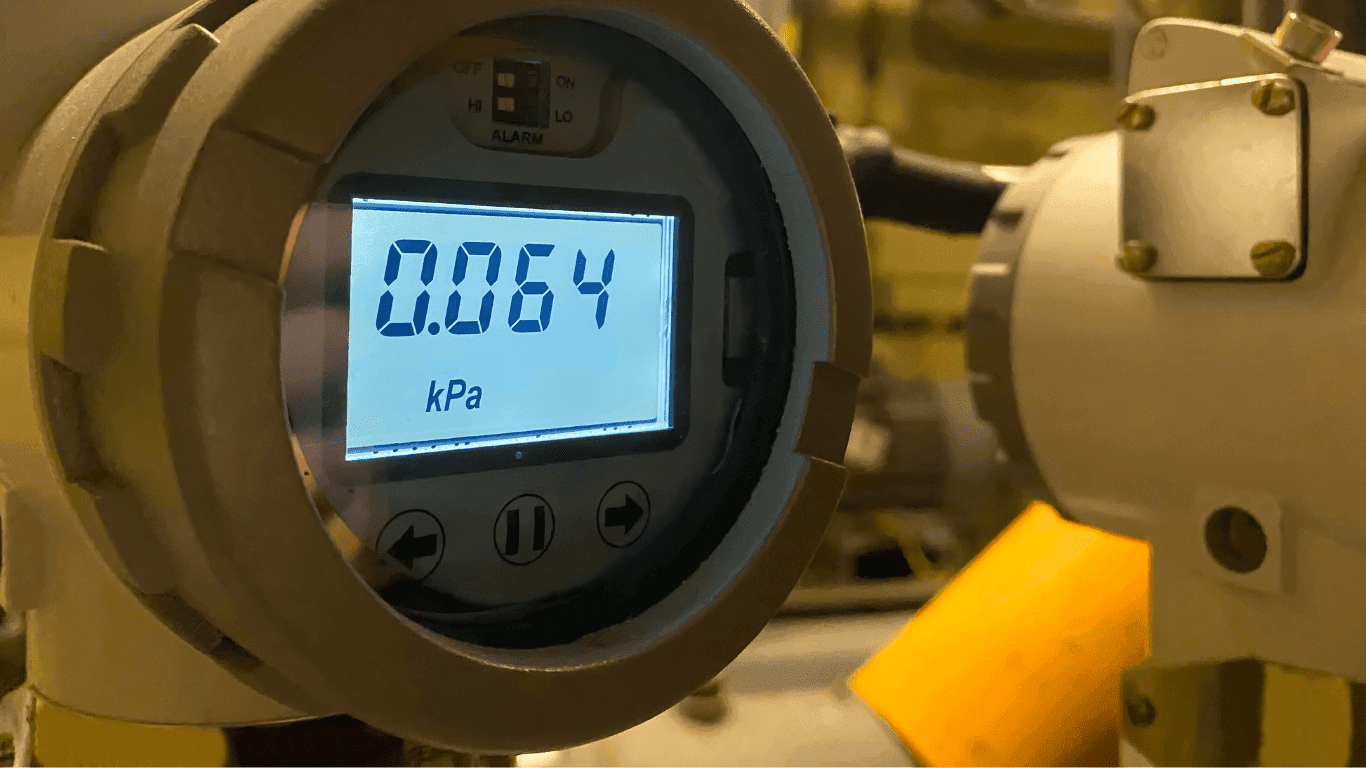

Helium and Leak Tests

Glass containers offer effective liquid sealing, but due to helium’s small size and absence of surface tension forces, specialized containers are needed for helium storage. Consequently, the leak tests and parameters for containers designed for these two fluids vary significantly.

Liquids and Leak Tests

Liquids have higher viscosity and surface tension than gases. The reason why it cannot pass through small holes called pores is the inhibition of surface tension. This physical phenomenon, which insects use to walk on water, explains that liquids cannot pass through the openings where gases can pass at pressures below surface tension.

Hazardous Gases and Leak Tests

It is acceptable for the tire pressure to decay to such a degree that refilling is required every 6 months. However, tests that may endanger human life or due to the working conditions of the product should be performed at much higher standards.

Causes of Leaks

- Importance of Material: Materials have a porous structure. Therefore, there are micro or nanocavities in them. These gaps cause fluids to pass through the product to the outside environment. Residual thermal stresses and shrinkage create cracks, voids, and pores in production methods that require high temperatures such as casting and welding. The ingredients are not perfect. Errors at the atomic level can cause leakage problems.

- Production Processes: Assembly errors, operator errors, errors caused by the machines used, or errors due to the normal distribution in tolerance are various reasons that cause the product to be leaky during the production phase.

Production processes involving these situations may result in leaking products, low customer satisfaction or products not performing their functions. It is important to update or fix their processes to avoid this result. Checking the final product with leak tests at the end of production is also an integral part of this process.

Since a “0” leakage rate is not possible, the next step is to determine the leak test parameters and choose a suitable test system. It is a sensitive process that requires expertise, such as the selection of the test method for the budget and needs, the implementation of this method, and its integration into mass production. Rubber hoses, medical catheters, and heat exchangers are just a few of the products tested with Adlema Leak Testing Devices.