New Generation High Precision Leak Test Applications

End-to-end leak testing solutions that meet the needs of different industries and meet all their standards.

Optimize your production process with Adlema smart leak test devices

It is an important quality control method to conduct leaks tests for all products during the manufacturing process. In this direction, you can test all products that come of your production line in seconds with the advantage of non-destructive testing offered by the ADLEMA Leak Test Product Family, which we have developed with our strong industry experience. With the non-destructive testing advantage of the ADLEMA Leak Test Product Family, which we have developed with our strong industry experience, you can test all products passing through your production line in seconds.

The worldwide trusted ADLEMA BT4000 series leak testing device is the industry leader with 98% more accurate solutions and 25% reduction in production costs, while being the right partner for safe test results.

Fast • Precise • Smart

Meet the precision that does not miss even the smallest leaks!

Leak Test Time Reduction

Production Cost Savings

Higher Test Accuracy

Customer Satisfaction

Trusted by:

We are stronger with you!

Powered by:

Always with us!

Latest Blogs

Follow our blog for leak test methods and more!

Negative Leak Rate in Leak Testing Before delving into the causes of negative leak rate,...

IP67 and Sealed Products Leak Tests In our blog post ‘Leak sealing of electronic...

Leak Testing of Electronic Components Since electronic devices are now present in every aspect of...

News

Adlema Machine Technologies at Web Summit in Lisbon!

Web Summit brings together over 70,000 individuals and companies redefining the technology sector. Europe’s largest technology conference will continue at the Altice Arena until November 16th.

For detailed information and participation, you can review the QR code at the end of the visuals provided for Turkish enterprises.

Details: https://websummit.com/

The countdown for WIN EURASIA exhibition has started!As Adlema Machine Technologies, we are looking forward to introduce our latest technologies to you at WIN EURASIA!

We are waiting for you with our expert team at booth number G100 in hall 8 at the event to be held on 7 – 10 June 2023. You can discover the quality and innovation of Adlema Machine Technologies with our leak testers, quick connectors apparatus and supporting products. See you at WIN EURASIA, we are waiting for you at the event!

Adlema Machine Technologies is excited to announce that it will be exhibiting at HANNOVER MESSE on April 17-21, 2023!

Our expert and experienced team will be waiting for you with our leak testing devices, quick connectors and additional products at booth D38 in Hall 5 to explain our solutions and experiences to the manufacturers of the industry about their leak testing needs. See you in Hannover, Germany! #HM23

We are attending CES 2023, world’s largest Consumer Electronics Show!

Our team, which will be in Las Vegas between January 5-8, is ready for the American market.

With the support of STKA, Automotive Exporters’ Association and ITU ARI Teknokent, we are waiting for you at the Eureka Park Turkey-Istanbul Pavilion at Las Vegas CES 2023!

At the fair, which will last for 4 days, we will be waiting to explain our solutions for your leak test needs with our leak test equipment, test apparatus and our expert team.

See you on January 5th!

Adlema is in the Big Bang Top 20!

The countdown has begun for the Big Bang Start-up Challenge, Turkey’s largest entrepreneurship event, supported by ITU Cekirdek, the ITU ARI Teknokent Incubation Center, where the best startups are determined every year. The rising initiatives of Turkey and the world will be hosted once again at the Big Bang. Breaths were held for this day when the best 20 startups were selected among the startups of the year. As Adlema, we are proud to be among the 2020 finalists.

Big Award to Adlema on Big Bang Stage

Big Bang Start-up Challenge, organized annually by ITU Cekirdek, the İTÜ ARI Teknokent Incubation Center, took place on Thursday, December 03. In the event, which was held online for the first time due to the pandemic, Adlema was awarded by the Istanbul Chamber of Industry and the Elginkan Foundation, which contributed to the production of value-added technologies by supporting new entrepreneurs in manufacturing. This year, a total of 3 startups, together with Adlema, were selected for the “Industrialist of the Future” award by the Istanbul Chamber of Industry. While a total of 175,000 ₺ awards were distributed to 3 startups selected by the Elginkan Foundation, Adlema was chosen for the grand prize and was deemed worthy of a 75,000 ₺ award.

Big Investment from TRAngels

We continue on our way with an investment of 1 Million TL from the TRAngels Team! TRAngels, which has invested in more than 40 startups in many fields from artificial intelligence, cloud, and mobile solutions, energy to biotechnology, and medical to food since the day it was founded, has invested a total of 6 million dollars to date. We are very happy that TRAngels, which has the potential to provide benefits in local and global markets, investing and consulting in venture projects, is a partner in our dreams on the way we set out to have a say in our field in the world.

Adlema is at International Fairs where Industry Professionals Meet!

We hosted many of our customers, stakeholders, and friends at our stand at WIN EURASIA (the meeting point of the Manufacturing Industry), Automechanika Istanbul (where thousands of automotive industry professionals from different parts of the world meet), and Saha Expo (the defense, aviation and space fair were technologies that shape the future meet). While we had the opportunity to introduce our high-value-added technology products to the representatives of the manufacturing sector, we gained a lot of new connections and cooperation potential. We have already started working for the day we will meet at the next fair!

TOFAS Go-Tech Event Held

Today we were at the GoTech21′ organization organized by the Tofas Connected Supplier team. In the presentation we made within the scope of the TOFAS GO-TECH program, we explained in detail our application in which the banjo surface and the hose are checked for leakage in rubber hoses with banjo connection, in order to increase the quality and traceability of the products we carry out together with TOFAS Turkish Automobile Factory. We would like to thank especially the TOFAS Turkish Automobile Factory team and all the participants who contributed to the organization of TOFAS GO-TECH.

IGA Istanbul Airport Prefers Adlema for Leak Tests of Lighting Elements

In terms of flight safety, the smooth lighting of the runways and therefore the leak tests of the lighting elements are critical. At this point, IGA Istanbul Airport relies on Adlema for the leak tests of the lighting elements of Istanbul Airport, the largest airport in Europe.

We were at the 15th Industry Congress

We were at the 15th Industry Congress, which was held with the theme of sustainability at the Halic Congress Center under the title of “Another Way is Possible”. We work to reduce carbon emissions in the long term by ensuring sustainable production, testing post-production leak-proof, and quality control of products.

And we say another way is possible with our work on “Industry, Innovation, and Infrastructure”, the 9th of the UN Sustainable Development Goals (SDGs)!

Artificial Intelligence and Robotics Hosts Adlema

Journalist Şule Güner, who specializes in artificial intelligence and robotics, covered Adlema in her column this week with the title “From traditional bubble testing in quality control to IoT and artificial intelligence application”. In her article, Şule Güner talks about showing the difference with the software in our hardware and breaking new ground in leak tests. Our founding partner Barış Hökevek talks about the leak tests and the advantages Adlema offers in the interview.

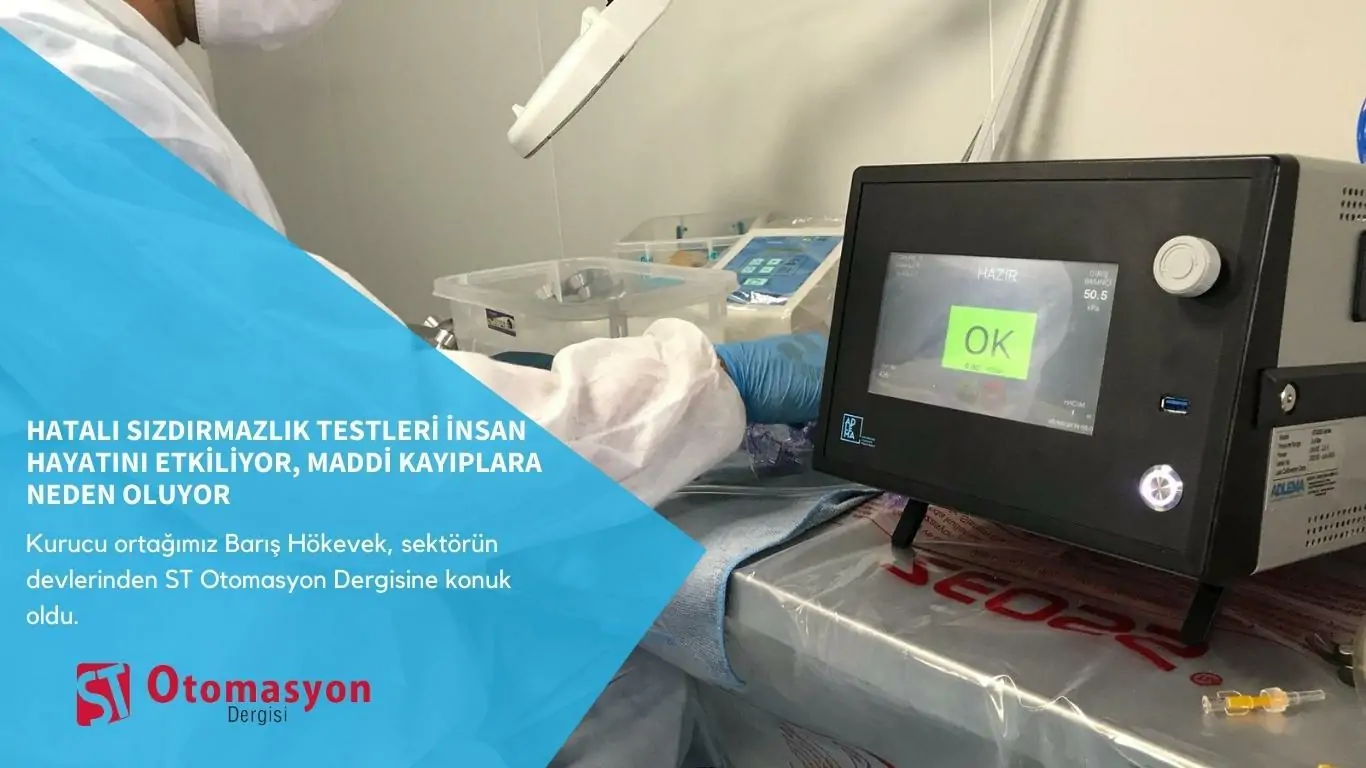

ADLEMA is in ST Automation Magazine, an Industry Giant.

Barış Hökevek, one of the founding partners of Adlema, explained in an interview with ST Automation Magazine, one of the biggest magazines followed by the industry, that the leak which can be detected by operators by spending minutes can be caught in seconds thanks to the device Adlema made. Talking about the solutions offered by Adlema, Mr. Barış said that a momentary mistake of the operators who observe bubbles in the water and decide whether the products are sound or not, may cause great financial losses and even negatively affect human life.

Why Adlema?

Work with us to carry out your leak tests under the consultancy of Adlema with our industry-leading technology and our team expert in leak testing.

High Precision

Precision that does not miss even the smallest leaks with its special measurement method and block structure.

Easily Reportable

Test reports created in the desired format can be monitored remotely using IoT, transferred to a computer with USB and analyzed in Excel format.

User Friendly

Test programs and parameters can be adjusted easily thanks to its 7″ color touch screen.

Flexible Design

It is designed in a flexible structure for special applications such as vacuum tests, moving parts tests, increasing and decreasing volume tests.

More Than a Leak Test!

How it works

Subscribe our newsletter

Choose the topics you are interested in. Do not miss the developments in the sector, case studies and current news about Adlema.