Test Parameters Determination

The first and most important step is to determine the test parameters for the product while performing the leak tests of a product during the production phase.

Is a “0” Leakage Rate Possible in Leak Tests?

Leak tests, a non-destructive testing method, are applied to products produced in many industries. At this point, manufacturers who invest in leak test equipment may expect “0” leaked products.

Who is Adlema?

Adlema, which is an expert in leak testing systems, is a fast-growing company that adds added value to the Turkish Industry.

Electric Vehicles and Leak Testing

Electric Vehicles and Leak Testing Electric vehicles have emerged because of the age of technology. In response to the need to create a sustainable future, engines that do not consume petrol, save fuel, operate with high efficiency and silence have been designed. Electric vehicles powered by this engine and battery are preferred more and more […]

Leak Test System Selection

Leak Test System Selection Many products must have leak-proof properties. It is an important quality control method to subject all products produced in the production process to leak testing. When performing leak tests, it is not the “0” leakage of the product that is sought, but its safe and functional operation in accordance with the […]

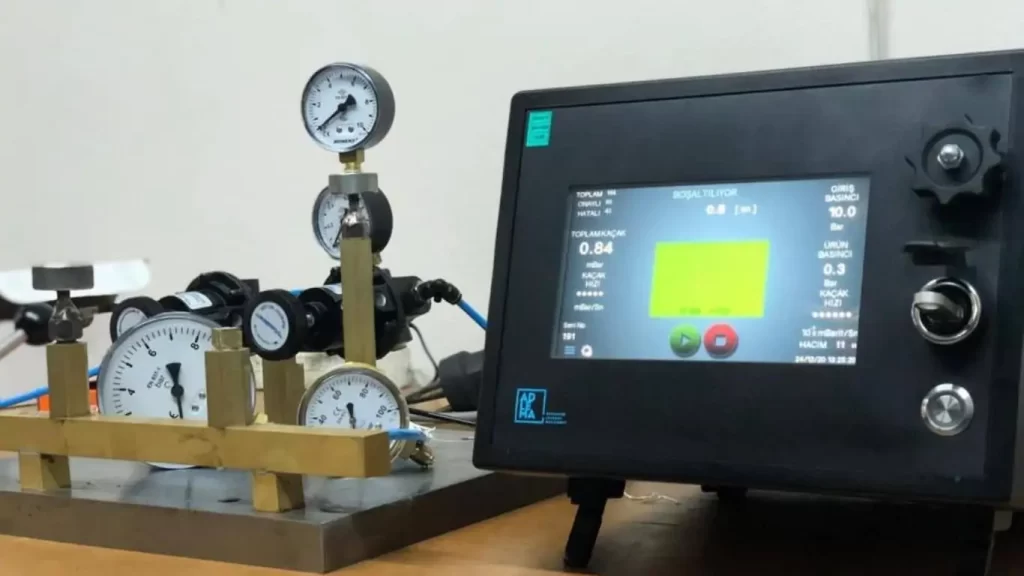

Understanding the Leak Testing Data

Leak testing devices automatically decide whether the parts are leaky according to the specified parameters. Various steps can be taken to check that the test is done correctly.

Negative Leak Rate in Leak Testing

Negative Leak Rate in Leak Testing Before delving into the causes of negative leak rate, we should first explain what negative leak rate is and how it is calculated. Negative leak rate occurs when the pressure drop of the part being tested is less than that of the leak-free reference part. Negative flow occurs when […]